Yesterday:

After the transom tabs dried, I pulled the wires holding the transom on. Amazingly, the tabs actually worked and the transoms didn't fall off!

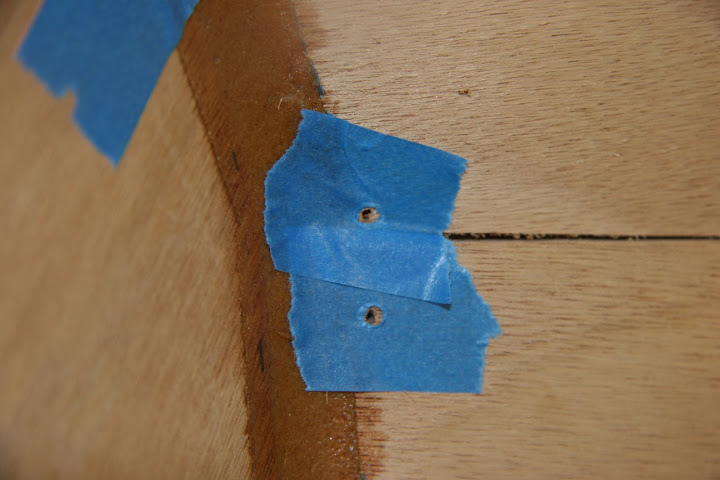

Since I wanted to fill the wire holes on the inside before I fiberglassed the bottom (especially the wire holes on the bottom), I began prepping for that in addition to getting ready for the final transom fillets. I stole a trick from "Kayaks You Can Build: An Illustrated Guide to Plywood Construction" by Ted Moores and Greg Rossel, and drilled a bunch of 1/8" holes in a roll of masking tape. I then tore off pieces of the tape and placed the piece over a wire hole to be filled, centering the 1/8" hole in the tape over the 1/16" wire hole. This was in hope of reducing the amount of sanding needed. I wish I had done that with the outside holes.

Next step was to lightly sand the tabs and wipe the area down with alcohol. Then it was time to add the final fillets to the transoms. I mixed up a batch of epoxy thickened to "peanut butter" consistancy - 3 pumps of goo, 8 spoonfuls of wood flour, 2 spoonfuls of silica and 1 spoonful of microlight. I loaded it into a freezer ziploc back (outside out this time!) and clipped off a corner. I squeezed out a line of the epoxy putty along the transom joints. I took a plastic putty knife that I cut down to a width of 1" (with a 1/2" radius curve) and spread the putty along the joint. This was much easier than adding the tabs because the wires were gone. Once I was happy with the fillets, I turned my attention to the wire holes. I squirted a dab of putty using the the ziploc back onto each of the masked wire holes. I took a gelato spoon and forced the putty into the holes and scraped away the excess epoxy putty. By this time, the epoxy was starting to set and I was racing against time to get all of the holes finished before it was too late. I managed to do it.

The second to final act for the night was to pull all of the tape. The tape along the fillets didn't take very long, although I had some trouble with it since I had taped it before adding the tabs and the epoxy from the tabbing had glued the tape down.

Pulling the tape off of the wire holes took nearly forever. This was because I was doing it with gloves on and I had trouble getting the tape up and when I did I had trouble getting the tape off my gloves and into the trash can. Plus there were about a million holes. Or so it seemed.

Pulling the tape off of the wire holes took nearly forever. This was because I was doing it with gloves on and I had trouble getting the tape up and when I did I had trouble getting the tape off my gloves and into the trash can. Plus there were about a million holes. Or so it seemed.On the other hand, the trick worked great:

The final task for the night was to run my gloved finger, wetted with alcohol, along the tabs to smooth them out. I also pressed down on each of the wire holes for good measure.

Today:

Time for the bottom fillets. I prepared a 2" wide plastic putty knife by cutting a 1" radius curve on the end of it. I placed this curve on the bottom-to-first-side-panel joint and marked where the knife touched the first side-panel along both of the joints. I then masked both sides of where the fillet would go. I also masked the gap between the 3rd and 4th panels at the stern. And for the fun of it, I masked the wire holes in the transom and the last few panel holes that had been masked when doing the transom fillets. I cleaned the intended location of the bottom fillets with alcohol and then wet it down with unthickened epoxy.

I mixed up another batch of "peanut butter" epoxy. I thought that the exising fillets were a little too dark compared to plain epoxy on the okume so I modified the recipe a little: 3 pumps of epoxy, 8 spoonfuls of wood flour, 2 spoonfuls of silica and 2 spoonfuls of microlight. I should have known better not to experiment with such a visible fillet, but since when have I thought before I've acted? This putty was much smoother than the previous batch. It was definitely lighter.

Same drill: load it into a ziploc bag, clip the corner, extrude the putty along the fillet joints, and smooth out with the rounded putty knife. I filled the wire holes and the gaps between the side panels at the stern. Lastly, I pulled the tape, which went much faster than the night before.

I have to say it looks pretty good. Except for the color. Hmmm. Definitely lighter than the okume. Rats. Now that I look closely at it, the transom fillets aren't really darker than the okume, just a different shade of brown. The extra spoon of microlight in my latest batch of epoxy made it too tan. Oh well, it still looks good.